"Dorelan has always been strongly connected to our territory, Romagna, as we believe that our business is not in opposition but in relation to creating value for our community.

We have asked ourselves many questions about the concept of doing business and sustainability, how our products can impact the environment, how we can be the link between different social realities at the territorial level, and how we can create value for our collaborators as well. The new approach, especially in the last four years, has had positive impacts on the environment and the community, and this improvement has been highly appreciated by the public and various stakeholders.

Heating system

Condensing heat generators ensure energy efficiency exceeding 100% and a low impact on the emission of pollutants such as nitrogen oxide (NOX) and carbon monoxide (CO). In production areas, low-temperature heating is used with underfloor radiant panels, which allow achieving efficiencies exceeding 100% of the calorific value of the fuel used (natural gas).

Water System

The thermo-hydraulic systems feature an automatic control system, while the operable skylights on the roof, as well as all the doors and entrances of the building, are managed by a building automation system equipped with a weather station. There is also an energy consumption monitoring system for various production departments and services.

Photovoltaic

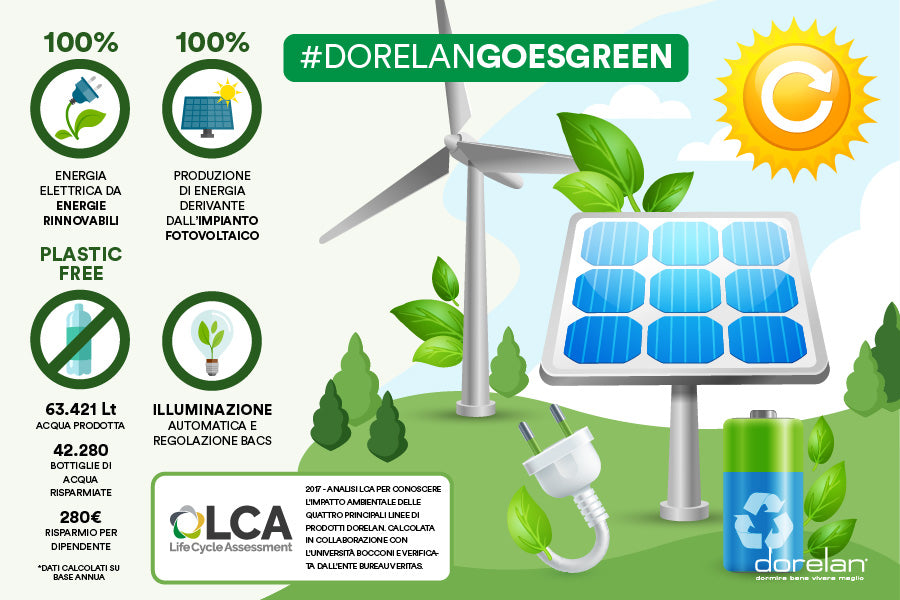

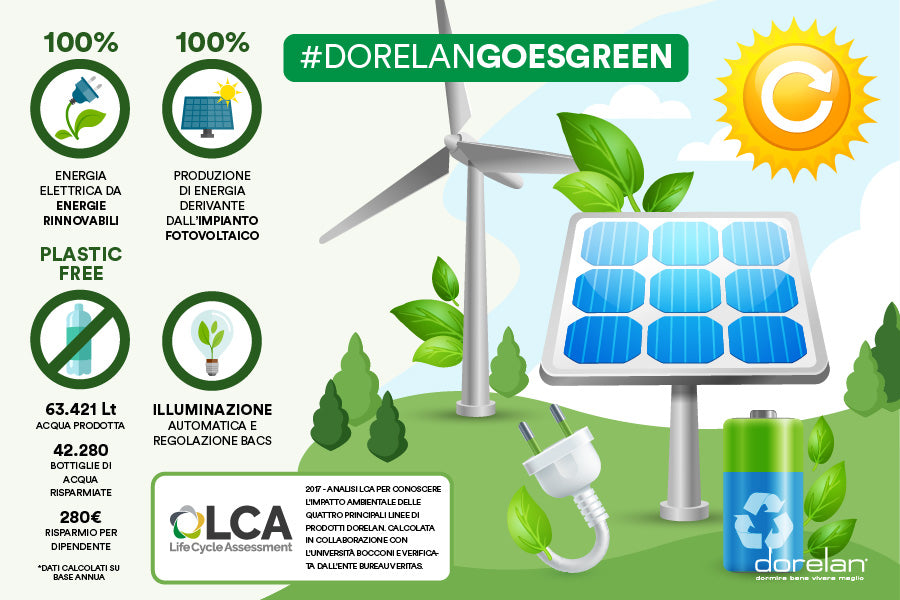

Dorelan is actively committed to implementing a sustainable policy aimed at reducing the environmental impacts of all its activities and improving the environmental performance of processes and products through employee training programs and interventions. The 62,000 square meters of production headquarters, nearly evenly divided between indoor and outdoor spaces, are powered by a photovoltaic system with a nominal power of 1 MW, which is able to self-generate approximately half of the company's entire energy needs. Some of this energy is fed into the national grid: in 2015, Dorelan transferred 703,170 kWh while purchasing 679,665 kWh from the grid (of which 30% came from renewable sources). This means that the facility produces all the energy it needs in a calendar year.

Photovoltaic

Dorelan is actively committed to implementing a sustainable policy aimed at reducing the environmental impacts of all its activities and improving the environmental performance of processes and products through employee training programs and interventions. The 62,000 square meters of production headquarters, nearly evenly divided between indoor and outdoor spaces, are powered by a photovoltaic system with a nominal power of 1 MW, which is able to self-generate approximately half of the company's entire energy needs. Some of this energy is fed into the national grid: in 2015, Dorelan transferred 703,170 kWh while purchasing 679,665 kWh from the grid (of which 30% came from renewable sources). This means that the facility produces all the energy it needs in a calendar year.

Water for employees

Not only attention to the environment but also care for employees: at Dorelan, two water stations have been set up with natural and sparkling water to allow employees to drink it for free during the day, avoiding the waste of plastic bottles and their subsequent disposal.

Illumination

The interior spaces are illuminated using a system with low-consumption and dimmable electronic fluorescent fixtures, equipped with presence and brightness sensors that reduce the flow and therefore the consumption of electrical energy automatically. Outside, state-of-the-art LED fixtures with very low consumption are used. The company also has an automatic regulation system called BACS (Building Automation Control System) for the coordinated, integrated, and computerized management of technological systems.

L'analisi LCA

La Life Cycle Assessment (LCA) è un’analisi che abbiamo condotto per conoscere l’impatto ambientale delle nostre principali linee di prodotto (Materassi a molle tradizionali, Materassi a molle indipendenti, Materassi in Myform, Guanciali in Myform) calcolato su tutto il loro ciclo di vita, a partire dalla produzione e fornitura delle materie prime fino allo smaltimento, da parte del consumatore, del prodotto finito alla fine del suo utilizzo.

L’analisi LCA ci permette di identificare tutte le informazioni utili per migliorare le nostre attività e quelle dei fornitori / clienti in ottica di un sempre maggior rispetto dell’ambiente. L’impatto ambientale di un prodotto è definito attraverso degli specifici indicatori, quali ad esempio le emissioni di gas serra (anidride carbonica), il consumo idrico e il consumo di risorse naturali. Ha verificato la nostra analisi LCA l’ente di certificazione Bureau Veritas, ente internazionale leader a livello mondiale nei servizi di controllo, verifica e certificazione per la Qualità, Salute e Sicurezza, Ambiente e Responsabilità Sociale. Bureau Veritas si è occupato di verificare il metodo, la qualità e la completezza dei dati che abbiamo utilizzato per quantificare l’impatto ambientale delle linee di prodotto prese in esame. Ci ha supportato la prestigiosa Università Bocconi di Milano affiancandoci docenti esperti nella gestione ed elaborazione dati per il calcolo degli impatti ambientali secondo la metodologia LCA.